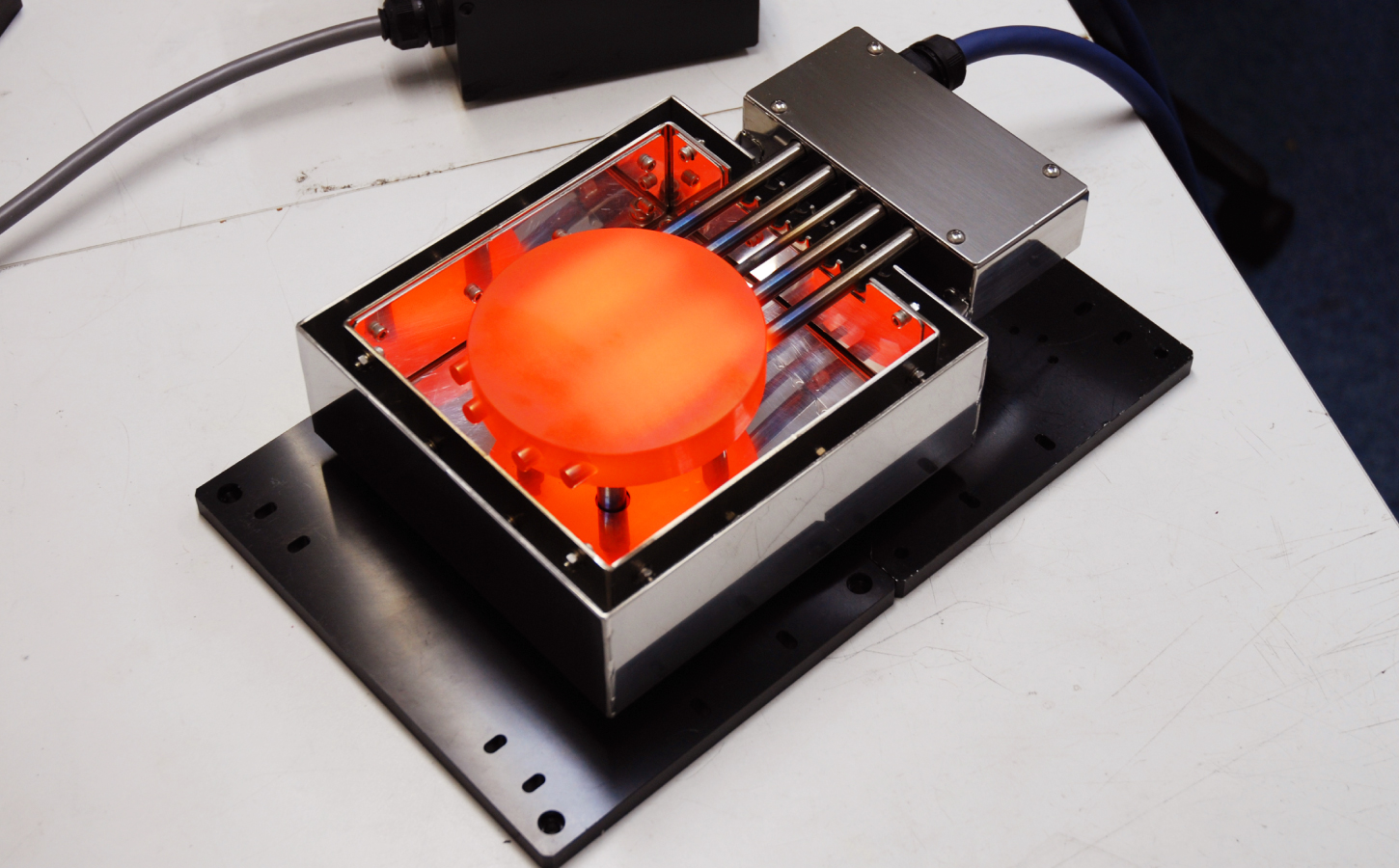

Super high temperature hot plate

Lineup of hot plate construction up to 1000°C maximum temperature

Main applications

Material surface research and evaluation, inorganic material heat treatment, heat resistance evaluation, baking, etc.

MSA FACTORY HEATING KNOW-HOW

We combine various expertise in materials (super heat-resistant plates, heat distortion countermeasures, titanium chassis) heater design, thermal insulation, thermal radiation, etc. High performance

Combined with the program type temperature controller /PCC107, the temperature can be controlled with high accuracy.

Toward an Automated Ashing Process

Compared to conventional burner processing, the programmable temperature controller allows for automatic process processing. This eliminates human error in processing.

Uniform heating structure to crucible

The insulation block structure ensures even heat transfer. Also, pre-treatment is possible in an integrated process, including treatment in a muffle furnace.

safety

Safety is taken into consideration in the heater design, wiring structure, and other aspects of the product. Controller/PCC110 with over-temperature monitoring function is also available. Please refer to the Super High Temperature_Heating Furnace Catalog 2025.

List of models

|

|

|

|---|---|---|

model number |

PA9005D |

PA9010 |

Max. temperature |

900℃ | |

Plate size |

50mm dia. | 100 x 100mm |

Plate Material |

Super heat-resistant alloys | |

Supply voltage |

AC100V | |

option |

Insulation block, | |

Temperature Controller |

Programmable temperature controller PCC107, others OP | |

PC Communications Software |

||

Special Features |

Automated ashing and ICP pretreatment |

|

Price (excluding tax) |

-

|

-

|

Catalog (general and individual) |

Ultra High Temperature Furnaces Catalog 2025 | Catalog PA9005D |

crucible cooling receiver

.jpg)